Technical Service Center

Our experts in the Technical Service Center will be happy to assist you with all application-related questions about materials, design and processing. Please do not hesitate to contact us!

Material Selection

- We support you in selecting the best material from our broad portfolio of Specialities, Advanced Products and Recycling-Compounds.

- As independent compounder, we develop tailor-made solutions and can produce the optimal compound for your application.

- Technical support and product trainings – also at your site!

Success Story

Altech NXT PP®

With Altech NXT PP® we close the gap between standard polypropylene and polyamide. This substitution enables the positive influence of global issues like lightweight construction or cost efficiency together with media resistance.

Design Support

- Support in the design of components and tools suitable for plastics.

- Consideration of material-specific characteristics in product design.

- Component simulations

- Filling simulation

- Mechanical simulation

- Thermal simulation

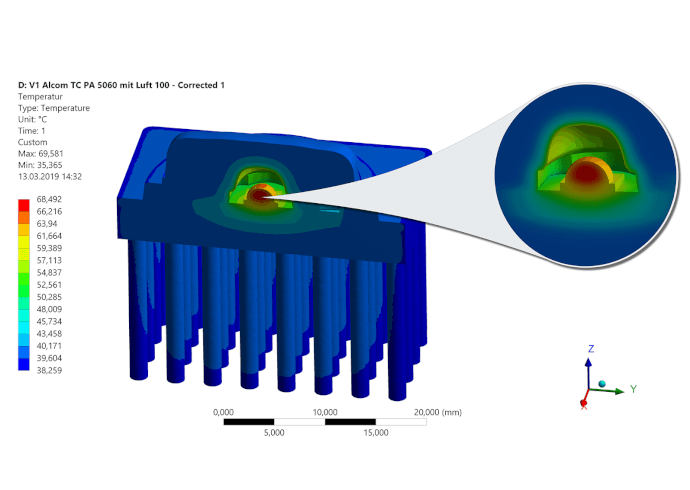

_4_3.png/jcr:content/2_DesignSupport_Simulationsbild_aus_ALTECH-NXT-PP-Produktflyer(Foto_in_PR)_4_3.png)

Success Story

Success through design!

Using the transient thermal structure-mechanical simulation (FEM) it was confirmed that the LED temperatures increased by only 1.5°C when comparing the innovative conductive plastic design to previously used aluminum. The simulated values are within the safe range and the intended lifetime of the LED could be guaranteed.

Processing & Process Optimization

- Consulting and support for process optimization from first sampling to serial production.

- Support for troubleshooting.

- Support for further and post-processing (e.g. welding).

- Trainings of your experts in processing and handling of our compounds.

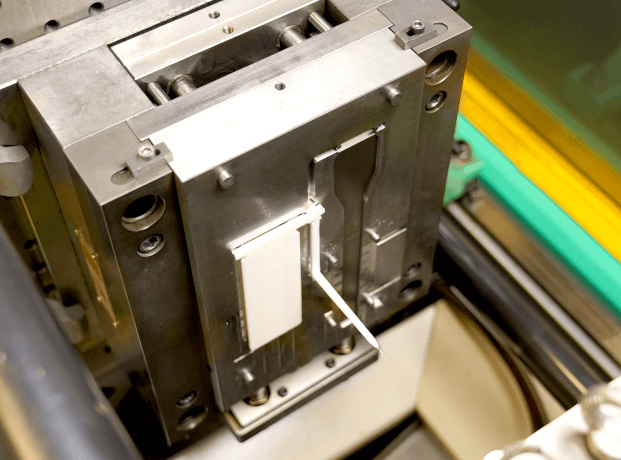

Success Story

2K injection molding

2K injection molding is gaining more and more importance. Thanks to the excellent polyamide adhesion and robust processing in 2K injection molding, our Alfater XL® 4PA series provides an efficient material solution for technically high-quality hard-soft parts in automotive, building & construction or general industries, among others. We can test possible material combinations in advance in our own laboratory according to VDI 2019. In combination with our know-how in plastics and processing, we support you in selecting the best materials as well as in set-up and optimization of your 2K injection molding process.

Material Testing & Sustainability

- We offer tailor-made compound and color developments according to customer request since 1961.

- Extensive material testing laboratory for the sustainable assurance of product quality and analysis of new product developments (e.g. mechanical, electrical or rheological tests).

- Cooperation with certified laboratories for special tests and material approvals.

- We provide support in sustainability topics related to our compounds. This includes, for example, information on recycling data as well as the calculation of global warming potential (GWP) using Sphera software.

Succes Story

Sustainable cell phone housing

With the recycling experience of MOCOM, a number of materials are already listed at various OEM. In addition to the mechanical requirements, the further processing requirements are equally relevant when selecting a drop-in solution. For example, the Altech® PC ECO material for the housing of the Fairphone® cell phone combines post consumer feedstocks with good processing, especially for painting. Even with a reduced Global Warming Potential (GWP) of 75 %, the processing and quality demands can be maintained.