Technical Consulting

True added value results from a calculation with many variables: only when technical know-how is solid, consulting is thorough as well as conducted at eye level and engagement is driven by maximum sustainability, does the end result satisfy you.

Our experts in Sales, Business Development, Technical Service Center and Product Development stand by you on all application-technical questions and development tasks related to material, design and processing. We aim to meet your requirements as much as our own standard of continually improving in what we do.

Material Selection

Finding the ideal material for an application is sometimes easier said than done – that’s something we experience repeatedly in collaboration with diverse companies. Therefore, we are happy to support you in selecting from our strong compound portfolio, driving you forward with innovative solutions and offering sustainable alternatives for many of our products.

Do you have unique or particularly challenging requirements for a product? As an independent compounder, we develop and produce solutions ourselves, tailored optimally to you and your application. Upon request, we support you with technical consulting and on-site product training.

Success Story

Altech NXT PP®

With Altech NXT PP® we close the gap between standard polypropylene and polyamide. This substitution enables the positive influence of global issues like lightweight construction or cost efficiency together with media resistance.

Design Support

If you need support with product design, we assist with plastic-appropriate component and mold design – always considering the material’s specific characteristics. If desired, we also perform various simulations to identify potential risks during the design process before they arise.

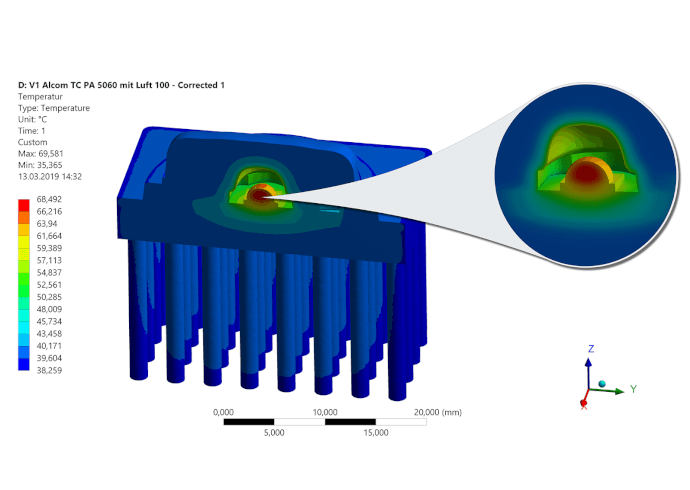

Through filling and component simulations or mechanical and thermal simulations, you gain crucial insights into how your chosen material performs under different conditions. With methods like transient thermomechanical finite element simulation, for example, we can detect temperature fluctuations within an application and thus make statements about product lifespan.

_4_3.png/jcr:content/2_DesignSupport_Simulationsbild_aus_ALTECH-NXT-PP-Produktflyer(Foto_in_PR)_4_3.png)

Success Story

Success through design!

Using the transient thermal structure-mechanical simulation (FEM) it was confirmed that the LED temperatures increased by only 1.5°C when comparing the innovative conductive plastic design to previously used aluminum. The simulated values are within the safe range and the intended lifetime of the LED could be guaranteed.

Processing & Process Optimization

Our experts also advise you on optimizing your processes and accompany you from on-site sampling to series production. We leverage our long-standing experience to identify and solve potential issues and support you in downstream processing and finishing.

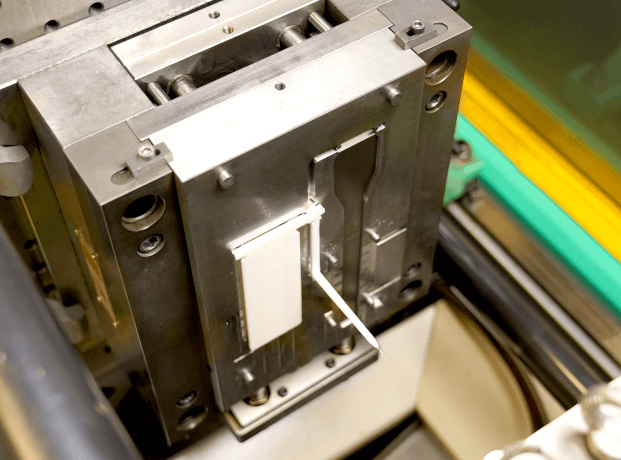

For example, if you choose our Alfater® XL 4PA for a 2K injection molding application, we can test potential material combinations in advance in our own technical center according to VDI 2019 and assist you with setting up and optimizing your injection molding process. To ensure you are well prepared for handling our compounds, we also offer process or processing training for your experts upon request.

Success Story

2K injection molding

2K injection molding is gaining more and more importance. Thanks to the excellent polyamide adhesion and robust processing in 2K injection molding, our Alfater XL® 4PA series provides an efficient material solution for technically high-quality hard-soft parts in automotive, building & construction or general industries, among others. We can test possible material combinations in advance in our own laboratory according to VDI 2019. In combination with our know-how in plastics and processing, we support you in selecting the best materials as well as in set-up and optimization of your 2K injection molding process.

Product Development & Material Testing

To meet the diversity of our customers, we have always offered customized product and color developments. And we do so where you are: we leverage extensive in-house development capabilities at our sites in Europe, the USA and China – with our own equipment and extruders that help us cover the full spectrum of our portfolio.

In our materials testing laboratory, we also ensure the quality of these new developments, conducting mechanical, electrical and rheological tests. For special and approval tests, we collaborate with certified external labs. Thanks to our long-standing experience in formulating our compounds, we combine OEMs’ precise color targets with the technical requirements of the chosen solution.

Succes Story

Tailor-made compounding

Thanks to the compound solution from MOCOM, which was individually tailored to the exact requirements of the OEM, the color targets as well as the necessary photometric properties could be achieved. A specific adjustment of the Alcom® LD2 formulation mastered the challenges during the assembly design and the strict timetable was finally reached by the customer.