# Products

10.10.2021

Cam Covers to become green - Altech® ECO enabling a lower CO2 footprint

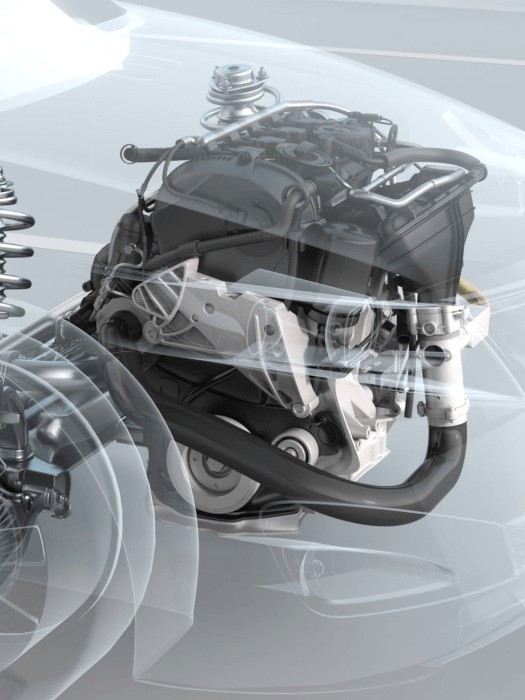

MOCOM and BRUSS Sealing Systems, a developer and producer of high-quality sealing systems for the automotive industry, worked in close collaboration to enlarge the use of sustainable materials. Under the hood applications Altech® ECO Near-to-Prime® Recycling compounds proved to be the right choice as a sustainable alternative in highly demanding applications where performance and value are the desirable criteria for a new cam cover for FORD.

The demand in the automotive industry for sustainable materials, recycled or bio-based, is continuously increasing. Consumers changed their mindset over the last years and OEMs recognized that the use of sustainable materials is becoming a selling argument.

“If OEMs have the choice between prime and ECO, they will always go for the more sustainable solution,” says Kurt Maschke, Director Global Marketing Automotive at MOCOM.

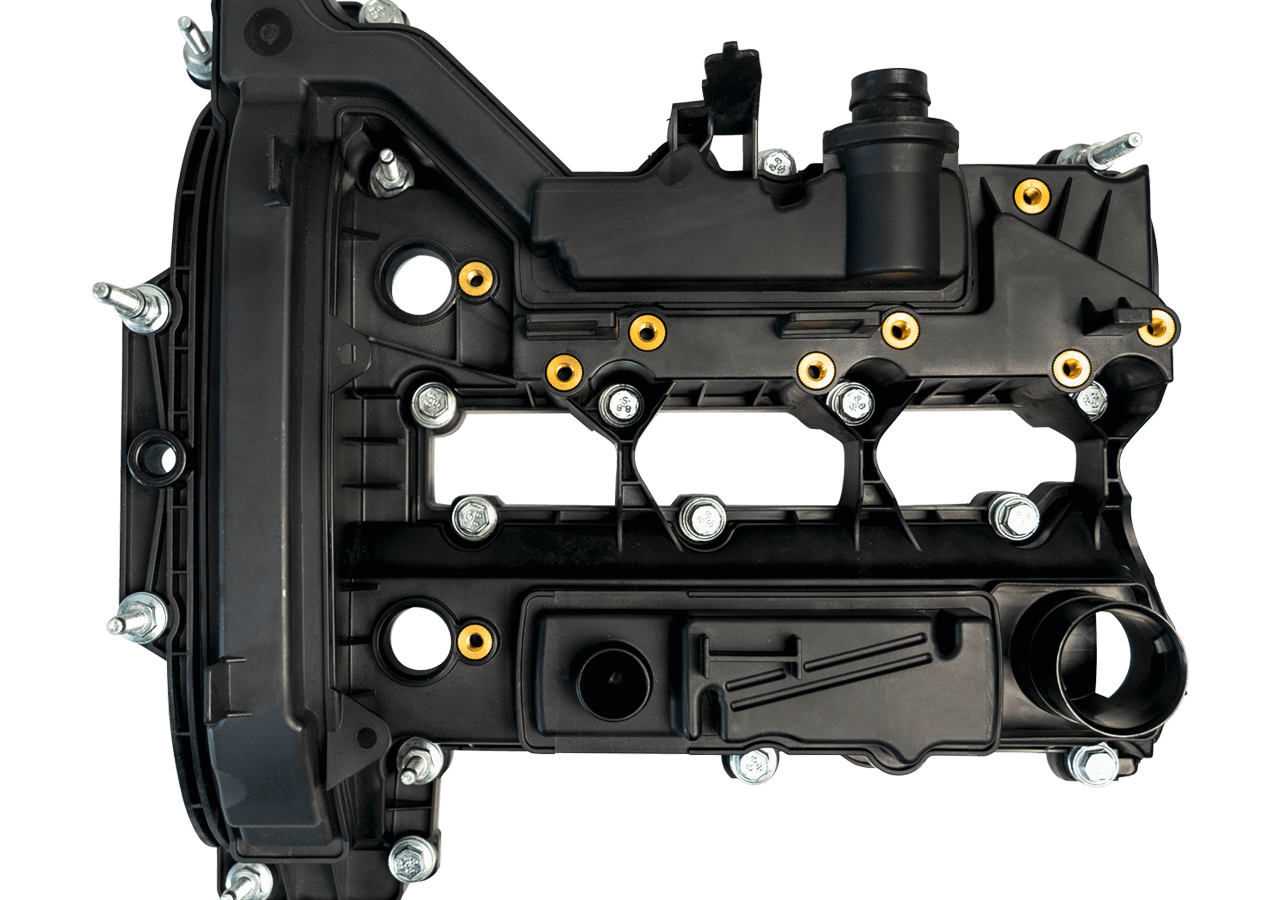

For high tech applications like cam covers, typically a prime PA66 GF plastic compound like Altech® PA66 A 2035/507 GF35 EF has been used. In cooperation with FORD, BRUSS and MOCOM developed, tested and approved a sustainable Altech® grade: ALTECH PA66 ECO 2035/500 BK2656-15.

This grade contains a high amount of Post-Industrial-Recycled (PIR) PA66 combined with prime glass fibers to fulfill the OEMs high requirements and standards for this application.

Typically hot oil storage and long term heat resistance are critical success factors for these applications.

“When located on the cylinder head, the cam cover in the Altech® ECO grade must show the same level of creep behavior as a prime grade under load from an elastomer gasket,” as the Ford project leader at Bruss explains. The component must create a secure seal using an elastomer gasket, and other components need to be fastened to the cylinder head cover with screw-in bushes.

In addition, the sustainable Altech® ECO material must be able to mold on the same tool as the prime material. Finally, the processability, i.e. injection molding and vibrational welding, of the cam covers with the sustainable material must remain on the same level as prime materials.

A durability tests of components also known as the vibration test has been undertaken on parts made out of Altech® ECO material and performed at the same level as the prime resin. The test determines the performance of the component and its strength under varying loads and temperatures.

Moreover, the benefits of recycled materials are evident as they can reduce the Global Warming Potential (GWP). Not only have recycled materials the advantage of causing a lower GWP value in comparison to prime materials but also their production, using green energy for the mechanical recycling process, is further reducing their carbon footprint.

Results calculated with the well-known GaBi software, which performs the analysis according to DIN EN ISO 14040 standard, show a CO2 reduction of 90% by using Altech® PA66 ECO 2035/500 BK2656-15 compared to the prime equivalent.

“Since the end of 2018, the serial production, using Altech® PA66 ECO 2035/500 BK2656-15, is successfully running in several applications. Apart from this grade, a complete ECO portfolio has been developed and is supporting customer needs of today and tomorrow,” says Julian Meier, Product Specialist at MOCOM.